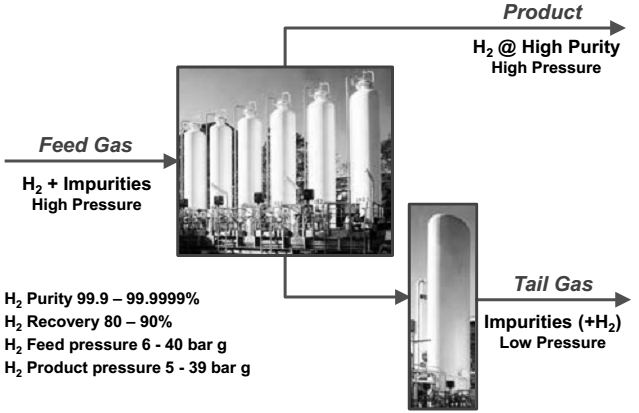

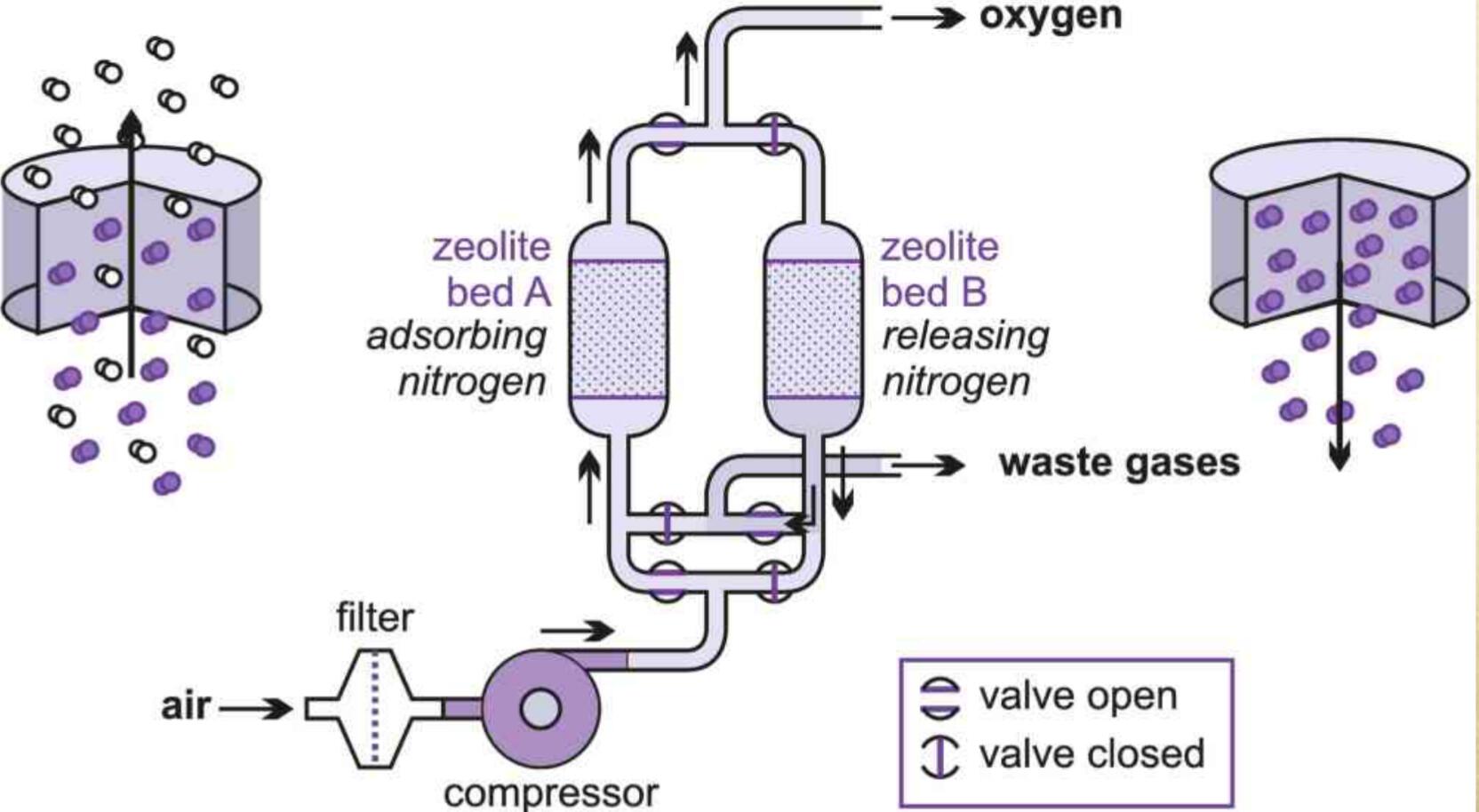

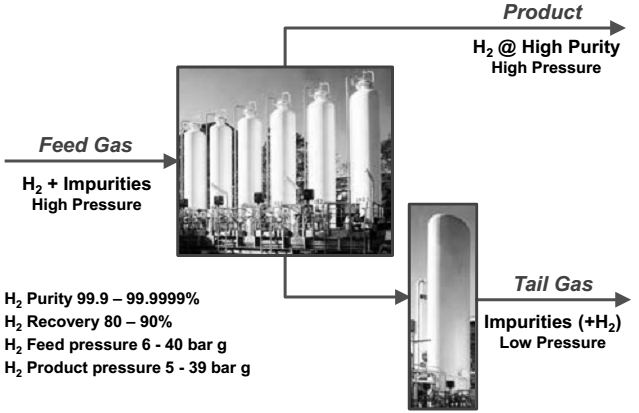

Pressure Swing Adsorption (PSA) has proved to be an effective and economic way for hydrogen recovery. Nowadays, the capacity of PSA system with multi-bed ranges from a few hundred Nm3/h to large scale plants with more than 400,000 Nm3/h. The hydrogen purity can reach up to 99.9999%.

EniSorb GPH-5 molecular sieve and activated carbon are key adsorbents to remove feed gas impurities such as CO, N2 and CH4. There are four main groups of users for a hydrogen purification system:

- Steam Reforming (Hydrogen Plants)

- Catalytic Reforming Net Gas

- Hydrocracker and Hydrotreater Purge Gases

- Hydrocracker Flash Gas

Click here to obtain technical properties of EniSorb Molecular Sieve GPH-5