EniSorb Activated Alumina Introduction

Views : 12603

Author : Jamie Shaw

Update time : 2020-06-27 17:10:52

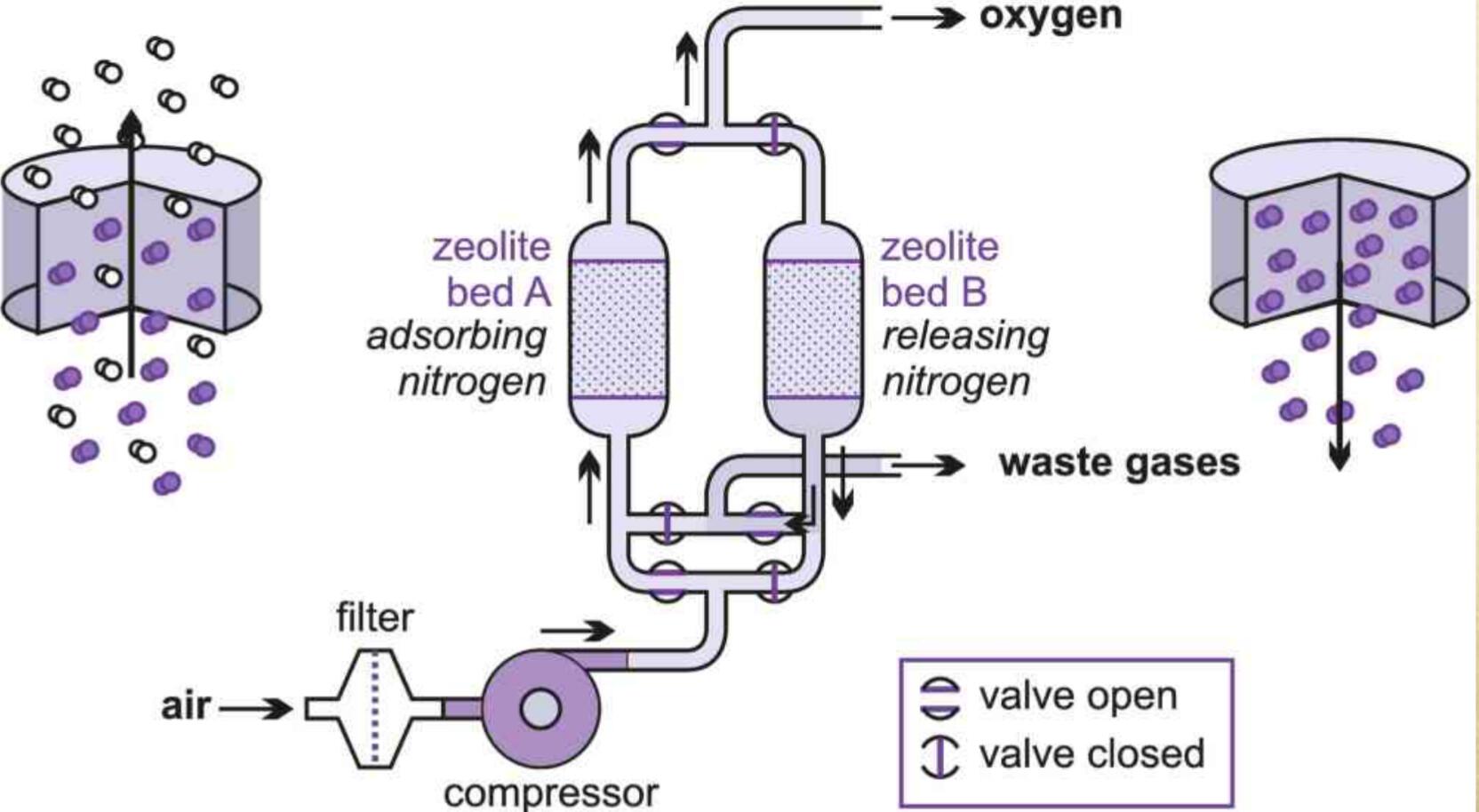

EniSorb Activated alumina is solid white spherical with a unique skeleton structure, it has uniform microporous distribution, strong water absorption capacity and good stability, mainly used in petroleum, chemical, metallurgy, electronics and other industrial gas phase, liquid phase drying, such as air, oxygen, nitrogen, ethylene, propylene, etc.

After a long period of research and development and production, Gophin chemical could supply activated alumina for multi-purpose areas as follow:

EniSorb-A01 Ordinary gas & fluid dehydration.

EniSorb-A02 Arsenic & fluoride removal in water treatment.

EniSorb-A03 Hydro gen Peroxide (H2O2) production.

EniSorb-A04 Catalyst Carrier.

EniSorb-A05 Compressed air drying.

EniSorb-A102A Claus sulfur recovery catalyst.

EniSorb-A102B TiO2 sulfur recovery catalyst.

EniSorb-A102C CuO desulfurizer catalyst

EniSorb-A111 Fe2O3 sulfur recovery catalyst

EniSorb-A104 Hydro gen chloride (HCl) removal from naphtha, natural gas, H2, N2, NH3, CO, CO2 feed gases.

EniSorb-A109 TBC removal in production of polythene and other polymers.

EniSorb-A202 Impurities (H2O, SO2, COS, H2S, ethers, ammonia and harmful substances) removal in petroleum refinery process.

Size range: 2-3mm 3-4mm 4-5mm 5-7mm 6-8mm 8-10mm 12-14mm 16-18mm

Packing: Plastic bag, super sack, steel drum, fiber drum, carton.

MOQ: 500kg

Regeneration: 180-350℃ temperature 4hrs nitrogen gas blowing.