The chemical industry has a large demand for carbon monoxide CO, such as TDI, ethylene glycol, formic acid, acetic acid, propionic acid, polycarbonate, polyurethane, dimethylformamide, dimethyl carbonate and other production processes require high purity CO.

Although CO resource is abundant, it usually co-exist with gases such as H2, N2, CH4, CO2…etc, needs to be separated and purified before they can be used. In addition, CO is also a harmful gas in most industrial gases. A small amount of CO can inactivate a variety of catalysts, thus needs to be deeply removed.In synthesis gas, water gas, semi-water gas, blast furnace gas, calcium carbide furnace exhaust gas, copper washing regeneration gas, Texaco furnace gas, converter gas, smelter, yellow phosphorus tail gas, coke generation gas, carbon black tail gas and some chemical plants,the tail gas contains a large amount of CO and H2, N2, CH4, CO2, water vapor, etc.. The separation and purification of CO as a chemical raw material has considerable economic value.

Traditional CO purification Methods:

The cryogenic separation method is the most commonly used method for industrial CO separation. The separation is achieved by the difference in boiling point of CO and other mixed gases, and it is suitable for large-scale preparation of high-purity CO. However, this method requires large equipment investment, complicated processes, high operating costs, and high energy consumption. It is cost-efficient only in the case of large-scale separation.

In the early 1970s, the American Tenneco Chemical Company developed the "Cosorb method". The absorbent used was a complex of copper aluminum tetrachloride and toluene (CuAlCl=·C6H5CH3). Its principle is to undergo the following complex reaction with CO:

CuAlCl4·C6H5CH3+CO →CuAlCl4·CO·C6H5CH3

By this method, CO is absorbed under the condition of pressurization at normal temperature, and it is separated from other components in the gas, and then the complex absorption liquid is decompressed and heated to desorb CO. The CO recovery rate of this method is high (≥99%), and the purity of the obtained CO can be more than 99.5% after toluene recovery treatment. However, the complex adsorbent will cause serious corrosion to the equipment, and the investment and operating costs are also high.

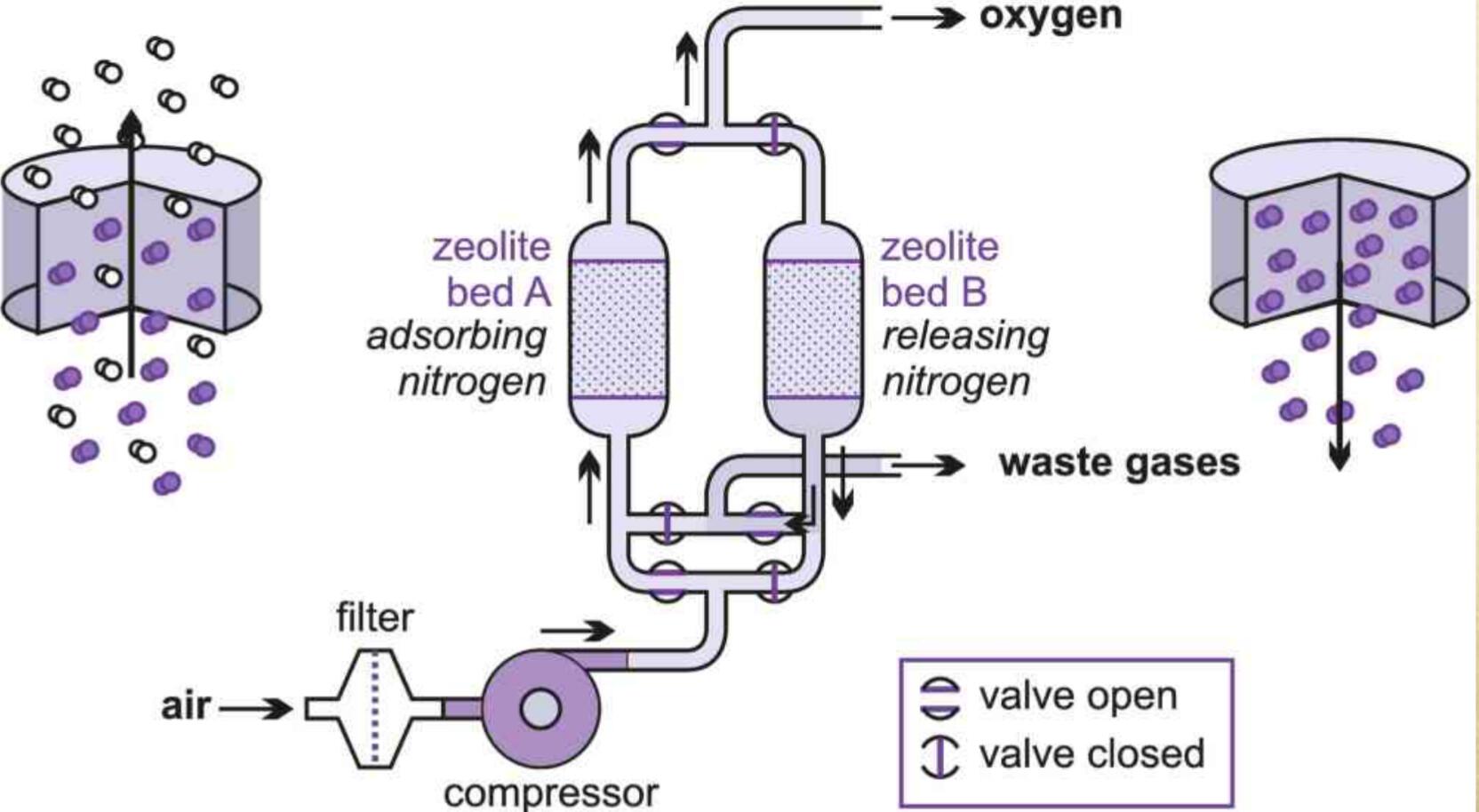

Pressure Swing Adsorption (PSA-CO) Method by CO Adsorbents

PSA-CO technology is to purify carbon monoxide from the mixed gas containing CO, H2, N2, CH4, CO2 and other components through the PSA process. The raw material gas enters the first-stage PSA device, adsorbs and removes CO2, moisture and a small amount of sulfur, and the decarburized purified gas enters the second-stage PSA device. The adsorbed CO is decompressed and vacuum desorbed as the output gas. The PSA-CO method has the advantages of simple process, high automation, easy operation, low energy consumption, no equipment corrosion and environmental pollution. The core of this method is the efficient CO adsorbent. Ordinary 5A and 13X molecular sieves cannot meet the requirements of industrial separation due to their low CO adsorption and poor selectivity.

Gophin GPCOS CO Adsorbent

GPCOS CO adsorbent has the advantages of large CO adsorption capacity and large separation factor of CO to N2, CH4, H2, CO2 and other mixed gases. It is suitable for pressure swing adsorption (PSA-CO method) to recover high-purity CO and deep removal of CO contained in mixed gas.

Technical properties of GPCOS CO Adsorbent:

Appearance: Blue-green, dark brown strip particles ( Dia: 1.6-2.0mm)

CO adsorption capacity: ≥48NL/kg (25℃,760mmHg)

Crushing strength: ≥40N (25pcs average)

Tapped bulk density: ≥0.75kg/L

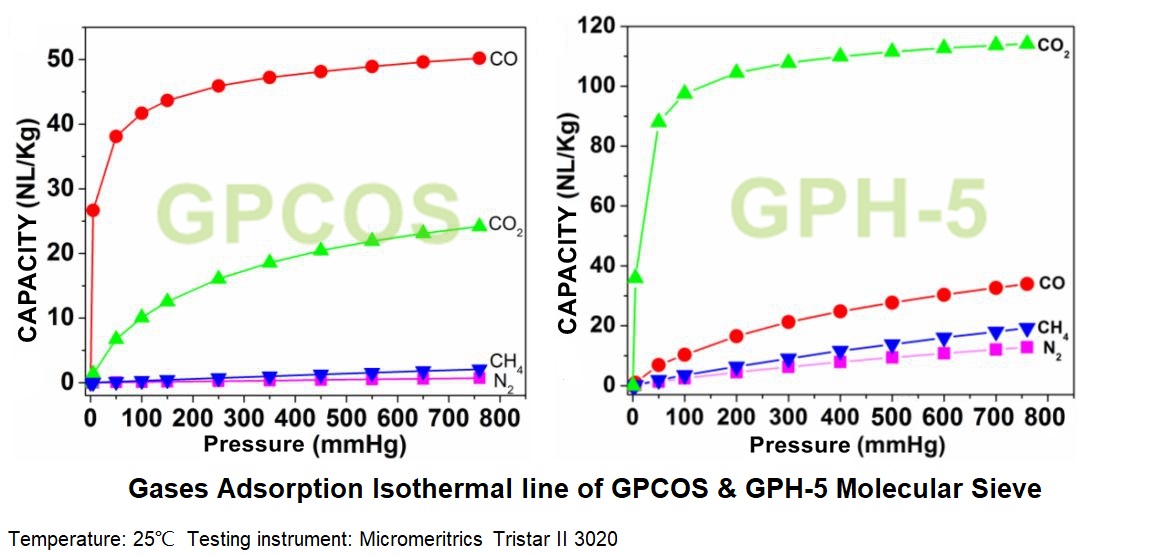

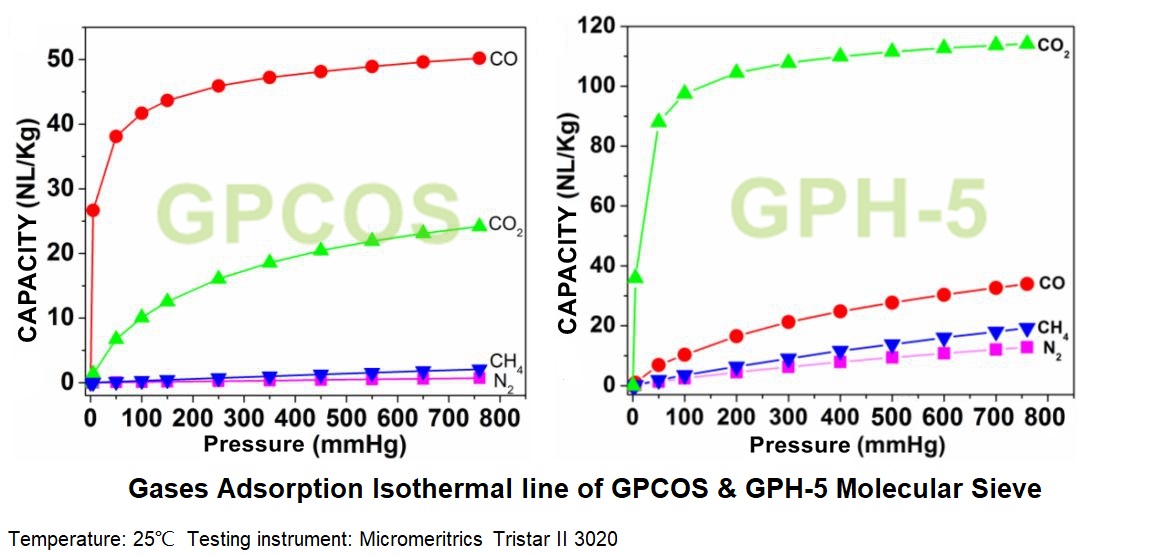

Comparison between the adsorption isotherms of GPCOS CO adsorbent and GPH-5 molecular sieve:

The figure below shows the adsorption isotherms of GPCOS CO adsorbent and GPH-5 molecular sieve to CO, CO2, CH4 and N2 at 25℃. It can be seen from the picture that GPCOS has a higher CO adsorption capacity than the traditional PSA GPH-5 molecular sieve CO adsorbent (GPCOS CO adsorption capacity: 50.2 NL/Kg, GPH-5 molecular sieve: 33.8NL/Kg pressure: 1 bar). In addition, the adsorption capacity of GPCOS for CO2, CH4, N2, etc. decreased significantly, and the CO/CH4, CO/N2, CO/CO2 separation coefficients were significantly improved, showing the excellent selective adsorption capacity of GPCOS for CO.

Experimental results

Experimental results

GPCOS molecular sieve's higher CO adsorption capacity and better selectivity make it have higher CO gas production rate and recovery rate in the practical application of PSA-CO method.

Welcome to contact us for information and quotation.